Andrew Zonenberg

azonenberg@ioc.exchange@dlharmon what are your thoughts on direct coax-to-PCB solder connections? Any experience, good or bad? How high of a frequency is it feasible to push this sort of launch to?

I've got several applications in mind, one only needs like 2 GHz of bandwidth while the other would ideally run from DC to Ku band.

The general goal is high density multi signal probing applications using .047" micro coax and jamming them in as tight as possible. Two lanes for initial testing using a GSSG or GSGSG tip geometry. Separate 50 ohm paths usable for either a diff pair or two independent single ended signals.

Right now I'm using SMPM which is pricey (especially for duals) and also still a little bigger than I'd like.

@azonenberg @dlharmon @g4dbn

Friend has simulated some stuff relating to that and it seems to simulate up to 20-30GHz with 0.086 semirigid at least.

The thing apparently is to get the launch really good.

So cutting a slot to the PCB for the coax and soldering it to the grounds was apparently critical for good return loss.

Our discussions and his simulations were mostly from the point of feeding LO to homebrew harmonic mixers.

Because I wanted to push 18GHz or preferably 38GHz to a 76GHz rig.

Andrew Zonenberg

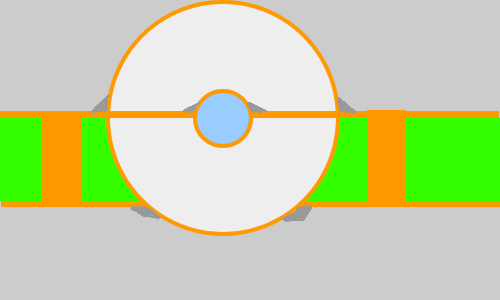

azonenberg@ioc.exchange@ftg @dlharmon @g4dbn So slot in the PCB with the center conductor flush with the surface?

I was hoping I could get decent results with the shield soldered to a top side ground layer then the center bent over. KF047 is only 1.2mm OD with the jacket removed, so there's not a whole lot of height variation to deal with vs .086.

@azonenberg @dlharmon @g4dbn

I'll link this thread to him and ask for input :D

But bending the center over gives an impedance bump and that limits the performance.

The main reason for cutting the slot was get rid of that center conductor to PCB trace bend and impedance bump.

Andrew Zonenberg

azonenberg@ioc.exchange@ftg @dlharmon @g4dbn Yeah, I get the concept. It's more a question of how bad things would be without it on really-small cable (where you might not even need the bend, just use more solder than usual).

The center conductor is 290 μm, dielectric 920, shield 1190.

So the difference in radius between the dielectric and center conductor is only 315 μm.

I guess the other question is how cheaply I could get my PCB fab to do controlled-depth milling...

@azonenberg @dlharmon @g4dbn

Asked the friend and this is roughly what he said (translated from Finnish).

1/x

-It is not only about the length of the center pin, but about matching the TEM wave in the coax to the quasi-TEM of the microstrip.

-If the transition can be done in a coplanar way, the match can get very good, especially if the center pin solder pad's size is properly matched.

-Matched structure in the slot can function above 30GHz.

2/x

- A direct, unmatched connection to a microstrip with some kind of coplanar-like top & bottom ground plane shape and plentiful amount of vias might do 15 - 20GHz.

- If soldered just directly on top of the PCB ground plane, then 5- 10GHz.

- The transition works better on a thicker PCB, because the microstrip being soldered to is wider.

Neil G4DBN

g4dbn@mastodon.radio@azonenberg @ftg @dlharmon I've tried using a ball mill to make a shallow groove for the shield tube and a 30 degree carbide engraving tool so the centre line of the centre conductor is level with the *bottom* edge of the foil. I didn't have a small enough ball mill at the time.

Neil G4DBN

g4dbn@mastodon.radio@azonenberg @ftg @dlharmon It seemed to work OK, it was only at 24 GHz though, but used 0.047" semirigid copper tube coax

@azonenberg @dlharmon @g4dbn

3/x

- The problems are the same as with coaxial connectors, if the ground path only goes from the bottom of the coax to the microstrips ground plane, the propagation mode of the coax is badly matched to the microstrip.

Some connectors try to mitigate that by having a small "roof" over the center pin solder pad to match the strayfields from the coax end.

@azonenberg @dlharmon @g4dbn

4/4

- The center conductor has big inductance and the face of the coax has large stray capacitance, with a suitably capacitive solder pad one can form a low pass. But the usable bandwidth of that match is not a huge amount of GHz.

It is better to minimize those elements to begin with.

- There is usually a lot less to be matched if the ground current can be made to flow on the sides of the coax in a co-planar way and not at one spot in the bottom.

And that is all

@g4dbn @azonenberg @dlharmon

According to my understanding this type of construction is among the best one can do in a homebrew setting.

I have a project that will have something like that in it.

After I mill some WR-28 to coax transitions.

Neil G4DBN

g4dbn@mastodon.radio@ftg @azonenberg @dlharmon I general, I cheat by not trying to use coax above 24 GHz, but I really should give it a go at 47 GHz one day. I'm thinking in terms of using spatial combiners though, all in waveguide, right from the device outputs. The detailed engineering needed to get excellent matches across coax to CPWG or microstrip is Officially Hard.