Neil G4DBN

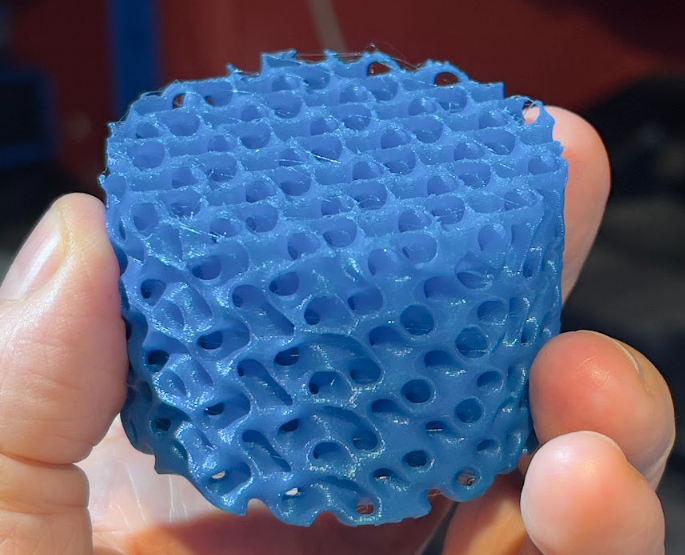

g4dbn@mastodon.radioFirst try at printing a gradient-index lens based on a variable wall-thickness gyroid lattice with the lattice surface meshes calculated using MATLAB code, then stitched and repaired, imported into Fusion 360, smoothed and then exported as STL into Prusaslicer and printed in PLA on the MK3S+ in the Prusa Enclosure.

UT3UMS 🇺🇦

UT3UMS@mastodon.radio@g4dbn wow that's impressive! Back then in university our teachers were not confident about such things and in 2023 it's 3D printable.

BTW, Maybe calculations can be done internally in OpenSCAD? Something like a factory of lenses, based on input parameters and it just generates an .stl, voila. I've also seen gyroid as an infill pattern option in Creality slicer, can it be related?

Neil G4DBN

g4dbn@mastodon.radio@gorplop The unit cell size determines the frequency range where it will work. It's best to use about 0.2 wavelengths, but a little more is OK. You also have to take into account the relative permittivity of the materials, so it ends up around maybe 1/10 of a wavelength or even smaller. At 30 GHz, that means a unit cell of around 1 mm for best results, which is getting close to the limits of precision of the resin process. There are some exciting ceramic sintering processes being developed.

Neil G4DBN

g4dbn@mastodon.radio@jmorris I'm having a few nightmares with material distortion at the moment, but I'm thinking of printing a large Luneburg lens in segments so I can test it more thoroughly. I'm trying to do 100 things at once though, and just wasted four hours trying to fix my old RasPi 3 running dump1090 for an ADSB feed to an aggregator to use in aircraft scatter communications. Turns out the image was SO ancient (wheezy), it was nearly impossible to upgrade. However, it is now shiny and lovely again. Phew!

Neil G4DBN

g4dbn@mastodon.radio@gorplop To get close to 1 THz, you start hitting material resonances. Even PTFE has a nasty suck-out at about 1.5 THz, then goes terrible above 8 THz. I've never done anything above 0.28 THz, but if I can get hold of devices, I'll have a go around 410 GHz. That's pretty serious stuff, and making measurements is pretty much impossible. When you get to 280 GHz, the waveguide sizes are sub-millimetre, and getting a fine polished finish is a huge challenge. 47 GHz is the end of my comfort zone